How to Build an Anechoic Chamber for Soundproofing and Acoustics in 2025

In an era where the demand for advanced soundproofing and precise acoustic measurement continues to grow, the construction of an anechoic chamber has become a critical focus for both researchers and industry professionals. According to a 2023 report by the International Society of Acoustics, the market for anechoic chambers is projected to expand at a compound annual growth rate (CAGR) of 7.2% by 2025, driven largely by advancements in technology and increased investments in R&D by various sectors. These specialized environments not only facilitate sound testing but also provide essential insights into material performance, noise reduction techniques, and auditory research, thereby enhancing product quality across diverse industries.

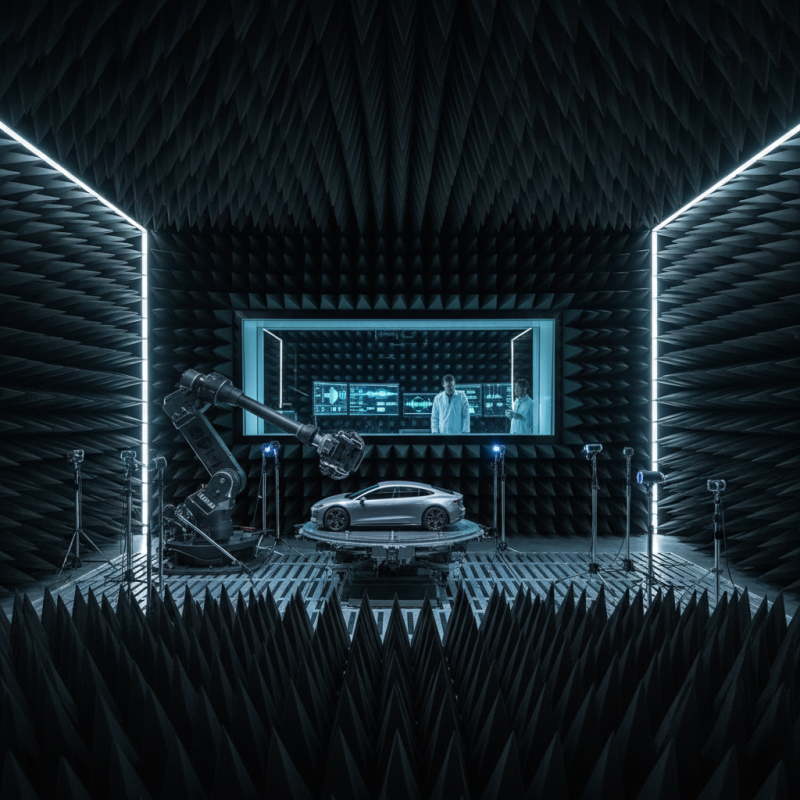

Dr. Amanda Lee, a leading acoustics expert and professor at the Institute of Sound Engineering, emphasizes the significance of these chambers: “An anechoic chamber is not just a room; it's a critical tool that allows us to isolate sound and gather data that is otherwise impossible to achieve in a conventional environment.” This fundamental understanding of controlled acoustics serves as a gateway to innovation in fields ranging from automotive design to consumer electronics. As the need for noise control and acoustic precision grows, the methodology for building and optimizing anechoic chambers is paramount for professionals seeking to ensure high standards in sound quality and performance.

Understanding the Fundamentals of Soundproofing and Acoustics

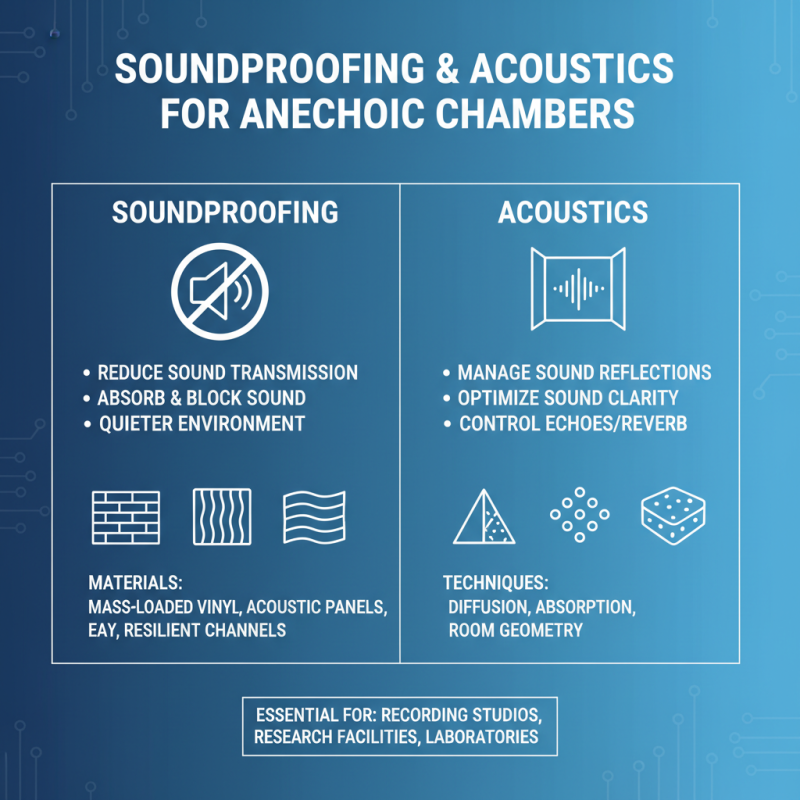

Understanding soundproofing and acoustics is essential when considering the construction of an anechoic chamber. Soundproofing refers to the techniques and materials used to reduce sound transmission between spaces, thereby creating a quieter environment. It involves both absorbing sound waves and blocking them, which is crucial in spaces where clarity and detail are paramount, such as recording studios, research facilities, and laboratories. Effective soundproofing starts with the choice of materials; dense materials like mass-loaded vinyl, specialized acoustic panels, and resilient channels are commonly used to minimize sound vibrations.

On the other hand, acoustics pertains to how sound behaves in an environment. This includes factors such as sound reflection, absorption, and diffusion. An anechoic chamber is designed to have minimal sound reflections, allowing for an almost complete absence of echo. This is typically achieved through the use of highly absorbent materials on the walls and ceiling, alongside geometric designs that trap sound waves. Within the chamber, one can analyze sound phenomena with an unprecedented level of precision, making it invaluable for scientific research and audio testing. Understanding these fundamentals is crucial for anyone looking to create an effective anechoic chamber that meets their soundproofing and acoustic needs in the future.

Key Materials and Technologies for Building an Anechoic Chamber

Building an anechoic chamber requires an understanding of key materials and technologies that contribute to effective soundproofing and optimal acoustics. According to a report by the Acoustical Society of America, the right combination of materials can significantly enhance sound attenuation, minimizing external noise and allowing for precise acoustic measurements. Commonly used materials include high-density foam, mineral wool, and mass-loaded vinyl, which help absorb sound waves and reduce reverberation. Recent advancements in sound-absorbing composites also show promising results, demonstrating the potential to improve performance while maintaining lightweight characteristics.

When planning the construction of an anechoic chamber, consider incorporating sound-diffusing elements to promote even frequency distribution. The use of strategically positioned diffusers made from wood or other natural materials can help mitigate any remaining reflections within the chamber. Additionally, sound isolation techniques such as floating floors and double-walled constructions are essential in achieving a truly effective chamber. The International Organization for Standardization (ISO) highlights that rooms designed with multiple layers of mass and absorption can achieve noise reduction values exceeding 50 dB.

**Tips:** Ensure proper sealing of all joints and seams to prevent any sound leakage, as even the smallest openings can compromise the effectiveness of the chamber. Moreover, regularly evaluate your chamber's acoustics using precision sound level meters and measurement software to fine-tune your setup for the best results. Always prioritize safety when handling materials, and consider consulting with an acoustics professional to optimize your design for specific acoustic testing requirements.

Design Considerations for Optimal Acoustic Performance in 2025

When constructing an anechoic chamber in 2025, several design considerations must be prioritized to achieve optimal acoustic performance. The first crucial aspect is the room's geometry. A rectangular or cubic shape is often favored to minimize standing waves, which can lead to destructive interference and skew sound measurements. Ensuring that the dimensions of the chamber adhere to specific ratios can help control low-frequency resonance, allowing for a more accurate representation of sound in an open environment.

Another essential factor is the choice of materials used for sound absorption. Utilizing advanced acoustic foam and specialized sound-diffusing panels can significantly enhance the chamber’s effectiveness. These materials should cover all surfaces, including walls, ceilings, and floors, to eliminate sound reflections. Additionally, consideration must be given to the construction of the isolation structure. This might involve building a double-walled design to prevent external noise intrusion while also incorporating floating floors to further reduce vibrations. By meticulously addressing these design elements, the anechoic chamber will not only serve its intended purpose but also provide invaluable insights into acoustic properties and sound quality assessment.

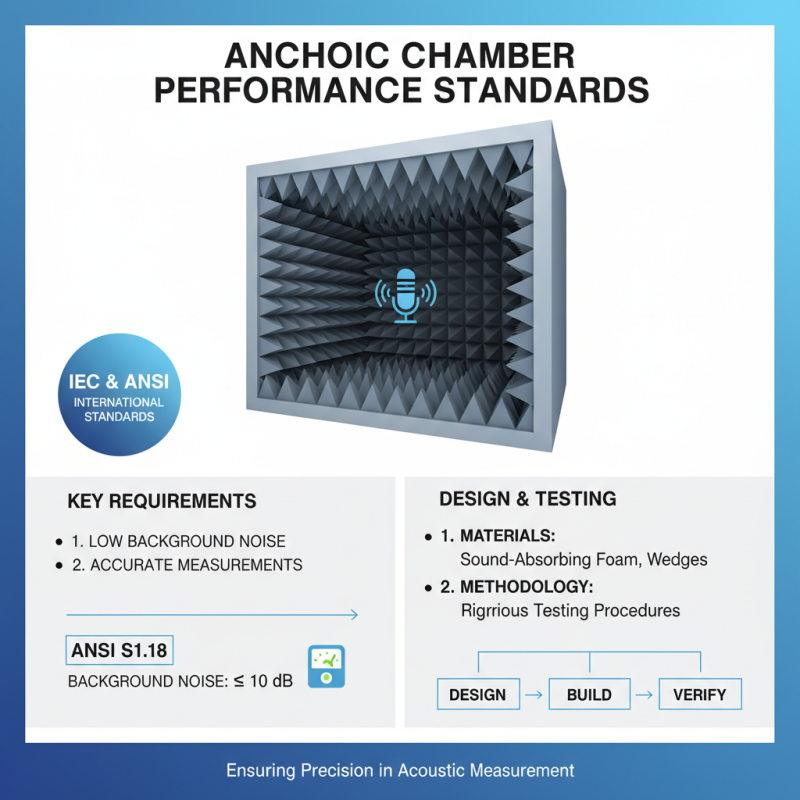

Measuring Effectiveness: Standards and Metrics for Anechoic Chambers

When constructing an anechoic chamber, effective measurement of its soundproofing and acoustic capabilities is paramount. The International Electrotechnical Commission (IEC) and the American National Standards Institute (ANSI) have established rigorous standards to ensure that anechoic chambers meet specific performance criteria. According to the ANSI S1.18 standard, an anechoic chamber must achieve a background noise level of 10 dB or lower, making it a critical environment for accurate sound measurements. These standards not only dictate the design of the chamber, involving materials such as sound-absorbing foams and strategically placed wedges, but also the methodologies for testing its efficacy.

Metrics for evaluating the performance of an anechoic chamber include sound absorption coefficients and the impact of spatial properties on sound propagation. A report by the Acoustical Society of America highlights that chambers achieving an absorption coefficient of 0.9 or higher across relevant frequencies provide a reliable setting for acoustic testing. Additionally, proper validation through empirical measurements, such as using a sound level meter to gauge sound pressure levels across various frequencies, is essential. These metrics not only confirm the chamber's compliance with industry standards but also affirm its effectiveness for research and development in acoustic applications, ensuring that findings are both reliable and reproducible.

Future Trends in Anechoic Chamber Design and Construction Techniques

The future of anechoic chamber design and construction is poised to embrace advanced technologies and innovative materials that enhance soundproofing and acoustic performance. One significant trend is the incorporation of sustainable materials, such as recycled composites and bio-based soundproofing elements. These materials not only reduce the environmental impact but also provide effective sound absorption, addressing the growing demand for eco-friendly solutions in acoustic engineering. Furthermore, innovations in 3D printing techniques allow for the creation of complex geometries that improve the internal acoustics of the chamber, optimizing the interaction of sound waves within the space.

Additionally, the integration of smart technology will redefine how anechoic chambers are designed and utilized. With the advent of IoT (Internet of Things), future chambers may feature real-time monitoring systems that assess sound levels and reverberation in real-time, enabling users to adjust settings dynamically for different testing scenarios. Machine learning algorithms could also analyze acoustic data to provide insights on optimizing chamber performance, paving the way for customizable and efficient acoustic environments. As these trends evolve, the anechoic chamber of the future will not only serve traditional testing purposes but also adapt to diverse applications across various industries, enhancing both product development and research capabilities.

Related Posts

-

2025 Guide: How to Choose the Right Anechoic Chamber for Your Testing Needs

-

Top 10 Facts About Anechoic Chambers You Need to Know

-

Top 5 Essential Acoustic Treatment Solutions for Home Studios

-

2025 Top Sound Treatment Panels: Elevate Your Audio Experience Like Never Before

-

10 Best Sound Deadening Panels for a Quieter Home Environment

-

2025 How to Use Sound Reducing Panels for a Quieter Home